Universal boilers Qtermo Trend N

| Trend 30N | Trend 50N | Trend 80N | Trend 100N | Trend 120N | Trend 150N | Trend 200N | |

| Volume (l) | 30 | 50 | 80 | 100 | 120 | 150 | 200 |

| Water connection | G 1/2 | ||||||

| Mains voltage (V) | 230∼ | ||||||

| Power(kW) | 1.6 | 1.6 | 2.0 | 2.0 | 2.4 | 2.4 | 2.4 |

| Current (А) | 7.0 | 7.0 | 8.7 | 8.7 | 8.7 | 10.5 | 10.5 |

| Heating time from 15 °С to 65 °С(hours) | 1.16 | 2.0 | 2.5 | 3.1 | 3.1 | 3.9 | 5.1 |

| Rated working pressure (MPa) | 0.6 | ||||||

| Safety valve pressure (MPa) | 0.7 | ||||||

| Overall dimensions | |||||||

| a (mm) | -- | 340 | 500 | 570 | 750 | 950 | 1230 |

| m (mm) | -- | 480 | 650 | 800 | 930 | 1125 | 1400 |

| d (mm) | -- | 515 | 544 | ||||

| Net weight (kg) | 16.2 | 19.7 | 27.4 | 29.4 | 32.4 | 38.5 | 52.0 |

| Recommended retail price (euro) | 165 | 167 | 180 | 200 | 225 | 258 | 326 |

* Prices in EUR are for reference only

-

Warranty for boiler tank

Warranty for boiler tank

2 year full warranty in Ukraine. -

All components are made in the European Union.

All components are made in the European Union.

EURO 1 certificate. -

Water protection. The external boiler casing is protected against direct water contact.

Water protection. The external boiler casing is protected against direct water contact.

-

Multiple

consumer

supply -

High quality

of thermal

insulation -

Anti-corrosion

protection with

an active anode -

Two dry

heating

elements -

Control of

water temperature

in the tank -

Quick

water

heating -

External

regulator of

water temperature -

High

energy

efficiency

Description of Qtermo boilers.

The Qtermo boiler is an electrically heated water accumulator with a special coating of high-temperature glass-zirconium enamel 550 microns thick applied by a liquid method, baked at a temperature of 850 degrees. Adding zirconium Zr to the enamel coating composition significantly increases its resistance to high water evaporation temperatures. The enameled zirconium coating protects the boiler internal tank during operation, and has proven itself in the long run regardless of the various water characteristics. The internal tank of Qtermo electrically heated boilers held is made of special low-alloy steel by Steel AG German manufacturer, and has a thickness of 2–2.2 mm (with 3 mm flange neck).

Dry Heating Technology: The heaters are located in special heat exchangers and have no direct contact with water. Unlike conventional heaters, this technology eliminates the damage of heating coils by scale, and significantly extends the service life and operation of the device.

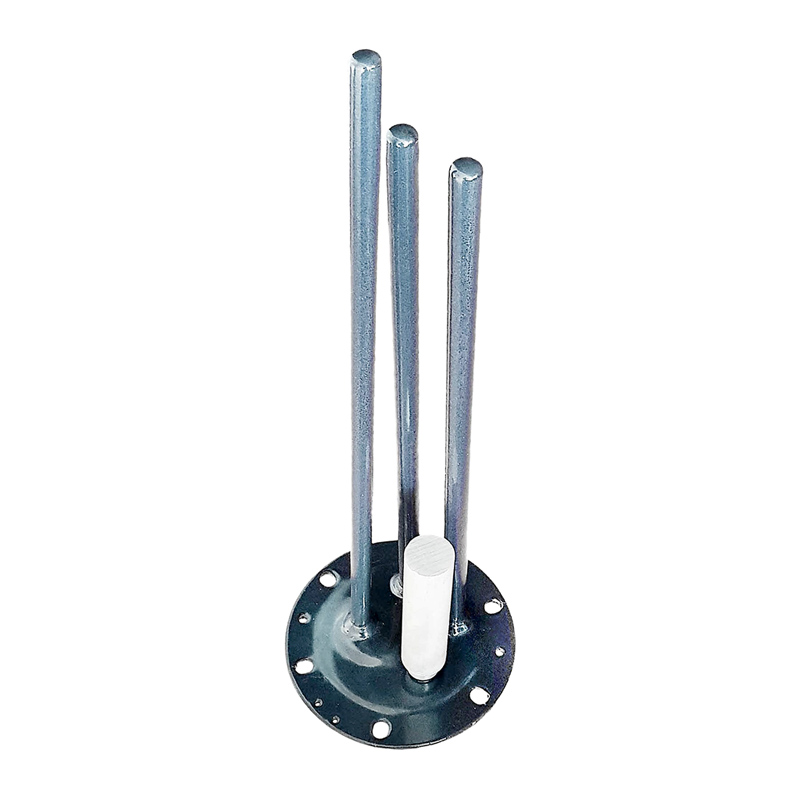

The flange of Trend N Dry type of dry heating element has a steel thickness of 3 mm and is attached to the boiler internal tank with 6 bolts through an elastic gasket, completely excluding leaks at the junction.

Boiler thermal insulation:

To ensure a high-quality thermal insulation, the internal tank is insulated with a thermal insulation layer of homogeneous polyurethane foam free from chlorofluorocarbons, made on the basis of a special recipe to produce a foam of very high density. The density of this insulation is characterized by one of the best thermal conductivity coefficients (= 0.022) with guaranteed minimum heat loss and maximum financial savings, and complies with the new EU standards on energy saving effective from January 1, 2016. The insulation density ensures minimum heat transfer from the water heated in the boiler; the insulation thickness reaches 45 mm.

Reliable COTHERM (France) electrical part meets European quality requirements.

Each Qtermo boiler is equipped with an enhanced active anode protection. This feature provides an effective protection, especially in case of higher oxygen content in the water, and greatly extends the boiler service life.

All components that make up the boiler are made in the European Union.

The tank assembly is performed in accordance with all existing standards of the European Union.

This is confirmed by EURO 1 certificate and certificates of conformity.